With a wealth of experience throughout industry, we work to reduce risk, reduce waste, and increase utilization.

We draw on our pool of SMEs and engineering resources to provide solutions that yield measureable integrity & reliability improvements. We make quality our priority at the outset of your project to ensure that all elements of the Mechanical Integrity program are successful. We can support for an entire implementation or aid in certain elements of your program, some of which include:

Mechanical integrity program implementation (from systemization to corrosion model and inspection planning)

Integrity Operating Windows (IOWs)

RBI analysis

Damage mechanism identification

Inspection strategy creation & inspection planning

Integrity data management & database management

Post inspection assessment of pressure containment integrity (including Fitness for Service assessments Level 1 to 3)

Anomaly management & strategy for remediation

API inspector support (510, 570, 653)

Interface between owner/operator and inspection contractors

Regulatory compliance for integrity & reliability

Reliability and maintenance engineering

We commonly find that our customers are suffering from one or more of the following pain points:

Too much inspection (non value added, lack of effectiveness)

The wrong inspection (techniques or locations)

Lack of process to handle anomalies

Incorrect or inadequate follow up inspection

Lack of future planning based on previous results

No documented plan or strategy for the allowance of NII (Non intrusive inspection)

Resolving these issues leads to drastic program savings and measurable reduction in operational risks and incidents.

API-579 Support

Helping you plan the future of your assets

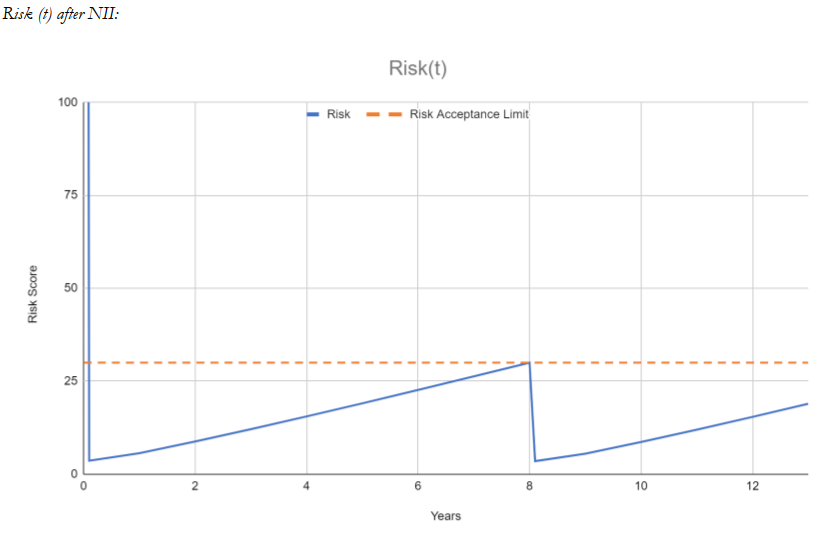

Risk Based Inspection

The future of your equipment, visualized